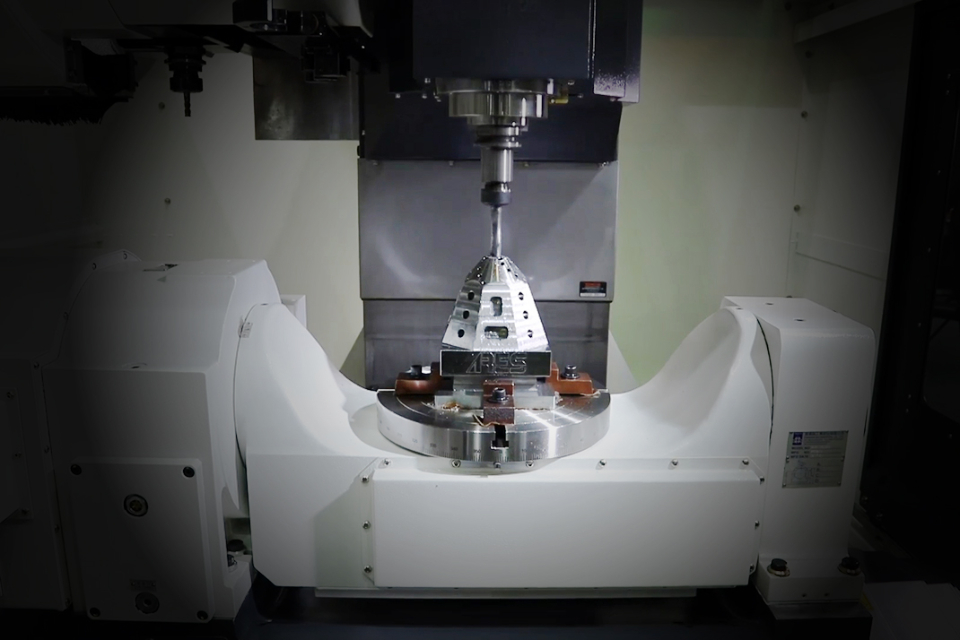

5 Axes Tapping Center

What is a Five Axis CNC Tapping Machining?

5-axis CNC tapping machining unlike traditional 3-axis CNC tapping machining centers, which operate on the X, Y, and Z linear axes, 5-axis tapping machines incorporate two additional rotational axes.

These extra axes allow the cutting tool to approach the workpiece from virtually any direction, offering a higher degree of flexibility and precision, this capability significantly reduces the need for multiple setups, letting the 5-axis CNC tapping machine process multiple aspects of a workpiece in a single procedure such as milling, drilling, and tapping can all be performed without repositioning the workpiece, leading to increased efficiency and reduced production time.

A Five Axis CNC tapping machining center is especially beneficial in industries that require high precision and complex geometries, such as aerospace, automotive, and medical device manufacturing.

AdvaAdvantages of 5-Axis CNC Tapping Machining

- The 5-axisThe 5-axis capability allows for the machining of intricate and complex geometries including undercuts, deep cavities, and contoured surfaces, this is something that traditional three-axis machining cannot do.

- With the ability to machine multiple sides of a part in one setup, the 5-axis CNC reduces the need for multiple fixtures and repositioning, saving valuable production time and increasing productivity and efficiency.

- By minimizing the number of setups and part movements, the 5-axis CNC machining center enhances overall part accuracy and consistency crucial for industries where precision is non-negotiable.

- The simultaneous movement of the five axes allows for smoother and more precise cutting paths, resulting in superior surface finishes reducing the need for secondary finishing operations.

- Optimal tool orientation and contact angles can be maintained throughout the machining process, which reduces tool wear and extends tool life, leading to lower operating costs.

High-Precision Machining Across All Industries

The Ares Seiki A5X Series five axis CNC tapping machining center is designed for industries that demand the highest levels of accuracy and efficiency, this advanced machining center is capable of performing complex operations on multiple surfaces of a workpiece in a single setup can handle a wide range of materials, including metals, plastics, and composites, making it a versatile solution for various applications such as aerospace, automotive, medical, and mold-making industries.

|

|

|